Read also

A comprehensive vineyard trellis design encompasses far more than simply installing posts and stretching wires between them. Professional trellis design integrates structural components, spatial planning, training systems, and material specifications. Together, these elements determine vineyard performance for decades.

For wineries planning new installations or renovations, understanding trellis design scope is essential. It ensures decisions that balance initial investment with long-term efficiency, grape quality, and maintenance needs.

Every professional vineyard trellis design begins with three fundamental structural categories that form the physical framework of the system.

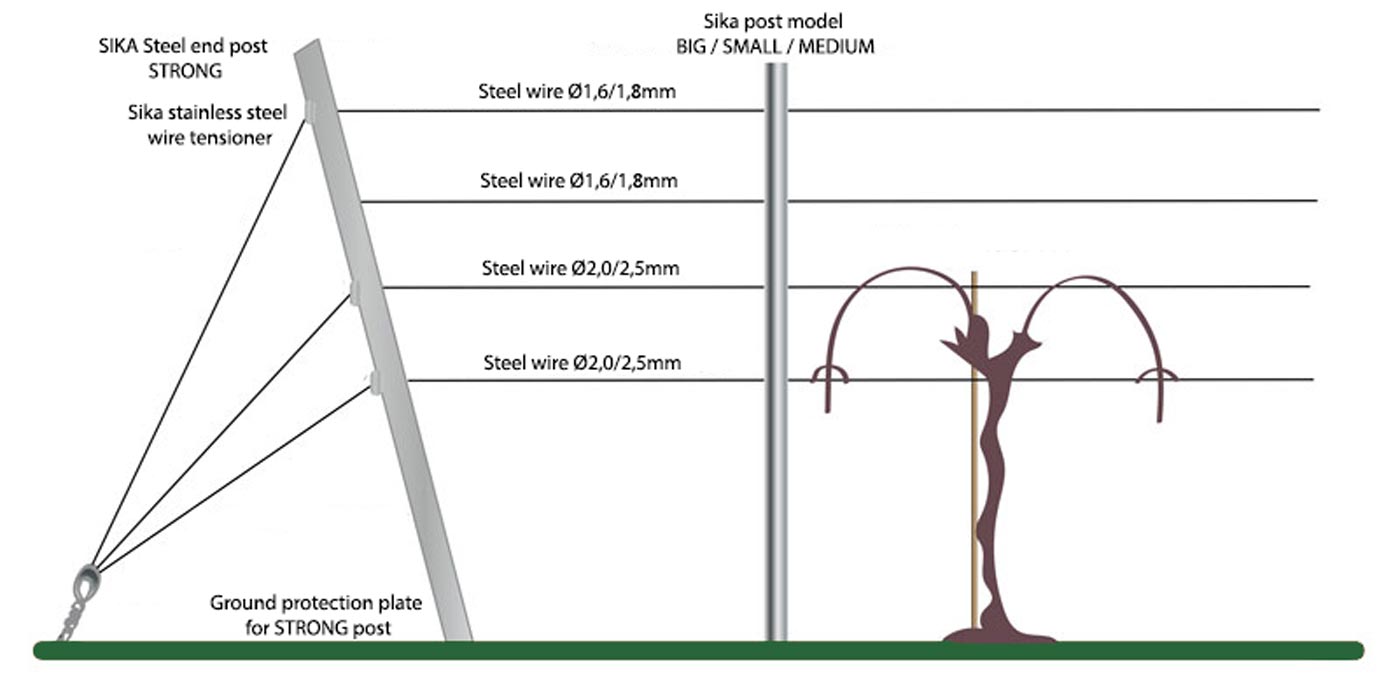

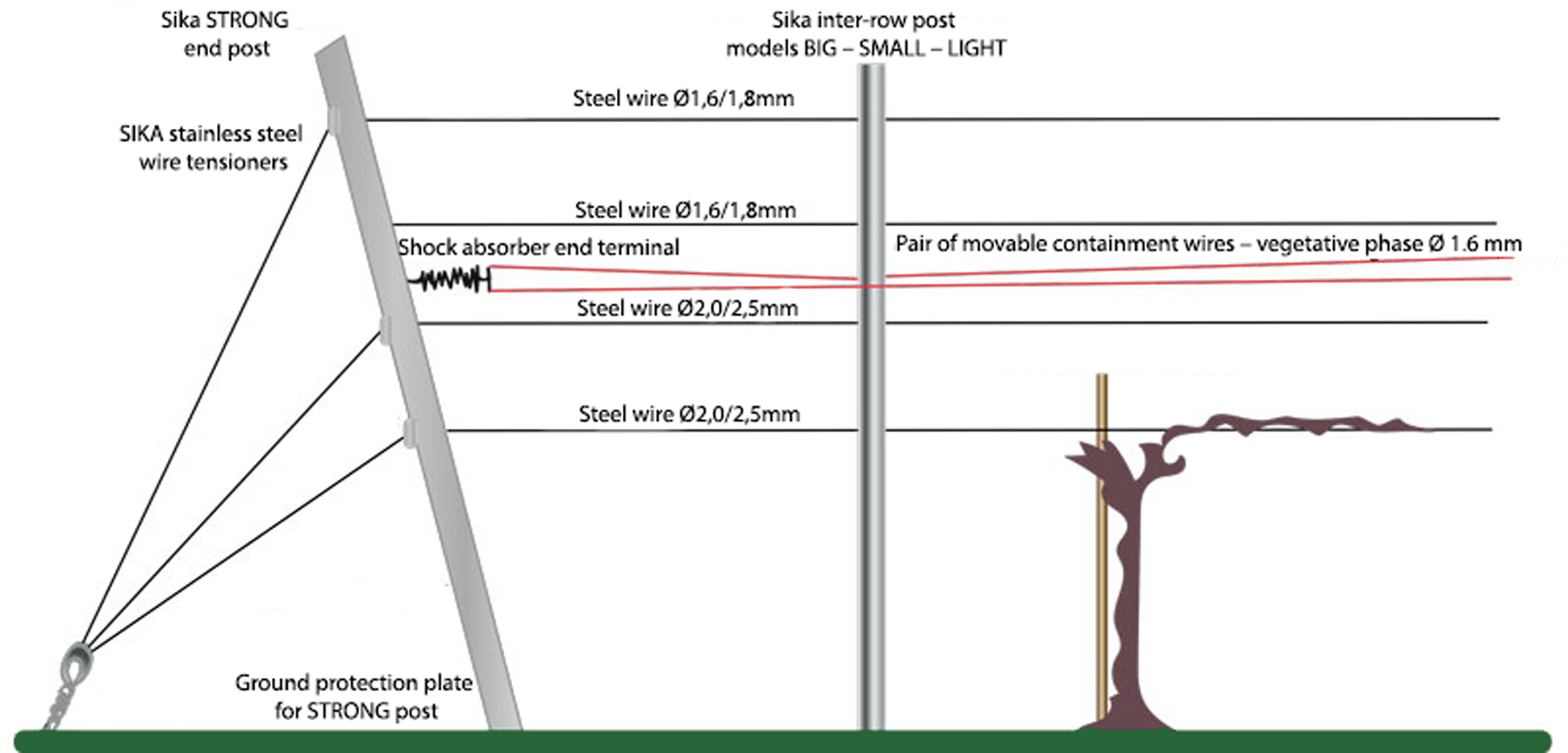

Metal vineyard posts form the vertical support structure. Line posts maintain row alignment, while end posts bear substantial tension loads at row terminals. These posts are manufactured from galvanized steel or corten steel and must meet height requirements typically ranging from 2.0 to 2.5 meters above ground. Cross-sectional dimensions must be matched to expected loads, with 65x45mm specified for heavy-duty applications and 51x33mm for standard vineyard installations.

The horizontal wire network forms the second critical component, consisting of primary fruiting wires positioned at specific heights determined by the chosen training system, along with upper catch wires that guide vertical shoot growth. Wire gauge, tensile strength, and galvanization must match vineyard lifespan goals. Environmental exposure conditions also influence these specifications. The third component category encompasses essential accessories that complete the trellis infrastructure.

These include wire tensioners that maintain proper tension throughout seasonal temperature variations, hooks and clips for wire attachment to posts, and spacers that prevent wire contact. Additional components include vineyard stakes for young vine support and anchor systems that stabilize end posts against cumulative wire tension forces that can exceed several hundred kilograms per row terminal.

Vineyard trellis design demands precise spatial planning that integrates multiple interdependent variables affecting both vine performance and operational efficiency. Post spacing along rows typically ranges from 4 to 6 meters. The industry standard of 5 meters balances structural support against material costs and labor. This spacing must accommodate the wire tension loads while preventing excessive wire sag between posts that would compromise canopy management.

Vine spacing within rows varies according to training system and vigor expectations, commonly ranging from 1.0 to 1.8 meters for quality-focused production. Row spacing between parallel vine rows typically spans 2.0 to 3.0 meters for vertical systems or expands to 3.5 to 4.0 meters for more vigorous training methods like Sylvoz or Casarsa.

These specifications impact tractor access, labor efficiency, and fruit zone microclimate. As a result, proper planning affects both operations and grape quality. Professional trellis design must also account for end-row turnaround space, access lanes for harvest equipment, and orientation relative to prevailing winds and sun exposure patterns that influence grape ripening uniformity.

The selection and integration of specific grapevine training systems fundamentally shapes vineyard trellis design parameters. For Guyot systems are adopted by over 35% of European quality wine producers. The design positions the first fruiting wire at 1.0–1.2 meters. Two or three upper catch wires, spaced 40 cm apart, guide vertical shoot growth. This vertical shoot positioning configuration requires posts of 2.0 to 2.3 meters and delivers excellent canopy aeration for premium fruit production on moderate-vigor sites.

Alternative training systems demand different trellis specifications. Cordon-trained vineyards may position their permanent cordon wire anywhere from 0.8 meters for low cordon configurations to 1.8 meters for high cordon systems, affecting post height requirements and mechanical pruning compatibility.

The Sylvoz system requires taller posts of 2.0 to 2.5 meters to accommodate its characteristic high horizontal cordon at the second wire level with fruiting canes arched downward to a lower wire. Each training system requires specific hole patterns for wire attachment at set heights. Therefore, post selection and training system decisions are inseparable during design.

Professional vineyard trellis design requires careful material specification to ensure structural integrity and corrosion resistance throughout the vineyard’s productive decades. When evaluating materials, consider these essential quality factors:

Effective vineyard trellis design requires more than quality components. It demands a manufacturing partner who understands the intricate relationship between structural specifications, training system requirements, and long-term vineyard performance.

Sika brings over 23 years of specialized expertise to vineyard trellis design, working directly with viticulturists and vineyard managers across 40+ countries to develop integrated trellis solutions tailored to specific site conditions and production objectives.

The company’s comprehensive approach addresses every design element, from structural components to complete accessory systems. Precision-engineered galvanized and corten steel posts feature innovative combined punching systems that accommodate multiple training system configurations. Complete accessory packages include wire tensioners, hooks, spacers, and anchoring systems that ensure structural integrity throughout the vineyard’s lifespan.

Sika’s ISO 9001, 14001, and 45001 certifications guarantee that every component meets exacting dimensional tolerances and material specifications essential for successful trellis design implementation.

Whether you’re designing a Guyot system for hillside quality production, implementing a Cordon framework for mechanized operations, or establishing a Sylvoz installation for vigorous varieties, Sika provides the technical consultation, material quality, and turnkey solutions that transform vineyard trellis design concepts into reliable, productive reality.

With over 400,000 posts delivered annually to professional vineyard operations worldwide, Sika stands as the trusted partner for trellis designs that perform reliably season after season, harvest after harvest.

Fill out the form to receive the catalog and get a free, no-obligation quote within 24 hours.